Bollfilter

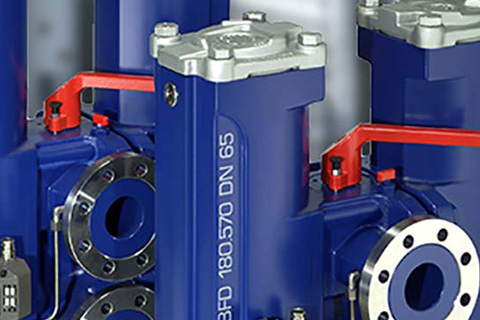

- Filters

- Automatic Backwash Filter

BOLL & KIRCH

BOLL & KIRCH - Duplex Filter

BOLL & KIRCH

BOLL & KIRCH - Simplex Filter

BOLL & KIRCH

BOLL & KIRCH - Fine Filter Unit

- Automatic Backwash Filter

- Membranes

- Applications

- Renewable Energy

- Protection of Water Systems

shutterstock

shutterstock- Exhaust Gas Recirculation (EGR)

- Ballast Water Management Systems

Adobe Stock

Adobe Stock - Exhaust Gas Cleaning Systems

iStock

iStock - Offshore Water Injection Systems

shutterstock

shutterstock - Floating Storage and Regasification Units (FSRU)

shutterstock

shutterstock - UV Systems in Wellboats

shutterstock

shutterstock - Sewage Treatment Plants

shutterstock

shutterstock - Potable Water Plants

Getty Images

Getty Images - Irrigation Systems in Agriculture

Fotolia

Fotolia - Irrigation Systems in Vertical Farming

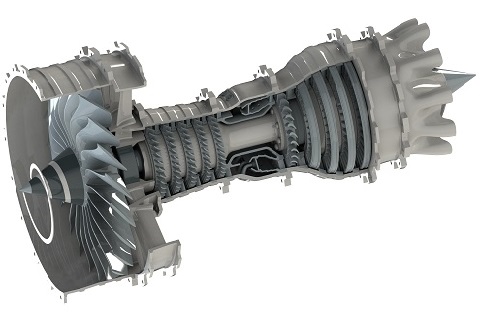

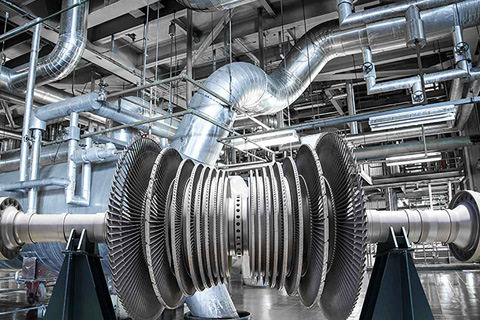

- Steam Turbines

shutterstock

shutterstock - Snow Machines

Fotolia

Fotolia - Desalination Process

- Heating Ventilation Air-Conditioning Systems (HVAC

shutterstock

shutterstock - Steel works

Getty Images

Getty Images - Pulp and Paper

- Exhaust Gas Recirculation (EGR)

- Protection of Engines

- Protection of Compressors and Turbines

- Protection of Machining & Cleaning Systems

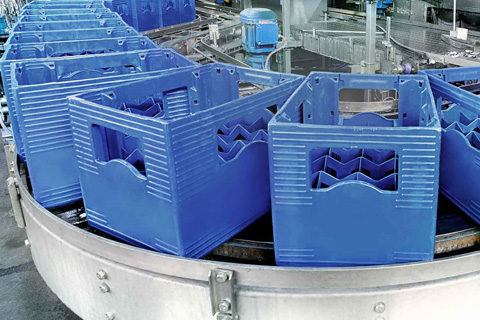

shutterstock

shutterstock- Bottle Washing machines

- Crate Washers

- Tunnel Pasteurisers

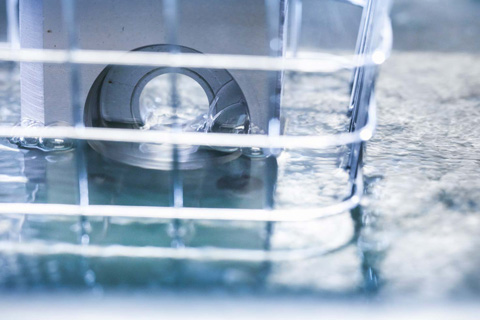

Getty Images

Getty Images - Part Washers

Getty Images

Getty Images - Machine Tools

Fotolia

Fotolia - Boiler Feed Water Pump in Power Plants

shutterstock

shutterstock - Heat Treatment

shutterstock

shutterstock - Pelletizing Plants

shutterstock

shutterstock

- Bottle Washing machines

- Renewable Energy

- Service

- Commissioning

- Maintenance

- Spare Parts

BOLL & KIRCH

BOLL & KIRCH- Filter Elements

BOLL & KIRCH

BOLL & KIRCH - Component Parts

BOLL & KIRCH

BOLL & KIRCH - Cleaning Industrial Filters

- Filter Elements

- Company

- Career

- Corporate philosophy

Adobe Stock

Adobe Stock - Corporate Responsibility

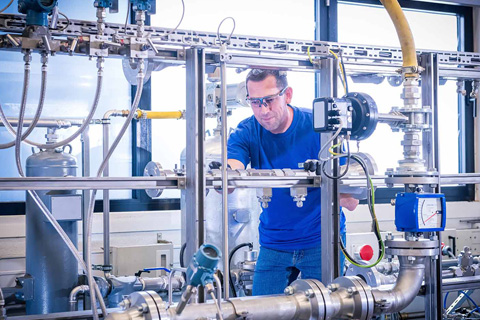

- Research & Development

BOLL & KIRCH

BOLL & KIRCH - Quality Management

BOLL & KIRCH

BOLL & KIRCH - References

- History

- Contacts

- Information

Suche anzeigen

x